Fire damage restoration can be incredibly challenging. This process often involves removing soot, smoke, and odors from various surfaces. Traditional methods of cleaning after a fire, such as sandblasting, chemical treatments, or manual scrubbing, can be time-consuming and may cause further damage to delicate materials. The aftermath of a fire often leaves behind stubborn residues that are difficult to remove without damaging the underlying surfaces. This is where dry ice blasting comes into play as an innovative and highly effective solution.

Dry ice blasting is quickly gaining popularity in the fire damage restoration industry due to its ability to clean surfaces thoroughly without causing damage. This method not only improves the efficiency of the restoration process but also minimizes the risk of additional harm to the property. As more restoration professionals recognize its benefits, dry ice blasting is becoming the go-to technique for dealing with the aftermath of a fire.

What Is Dry Ice Blasting?

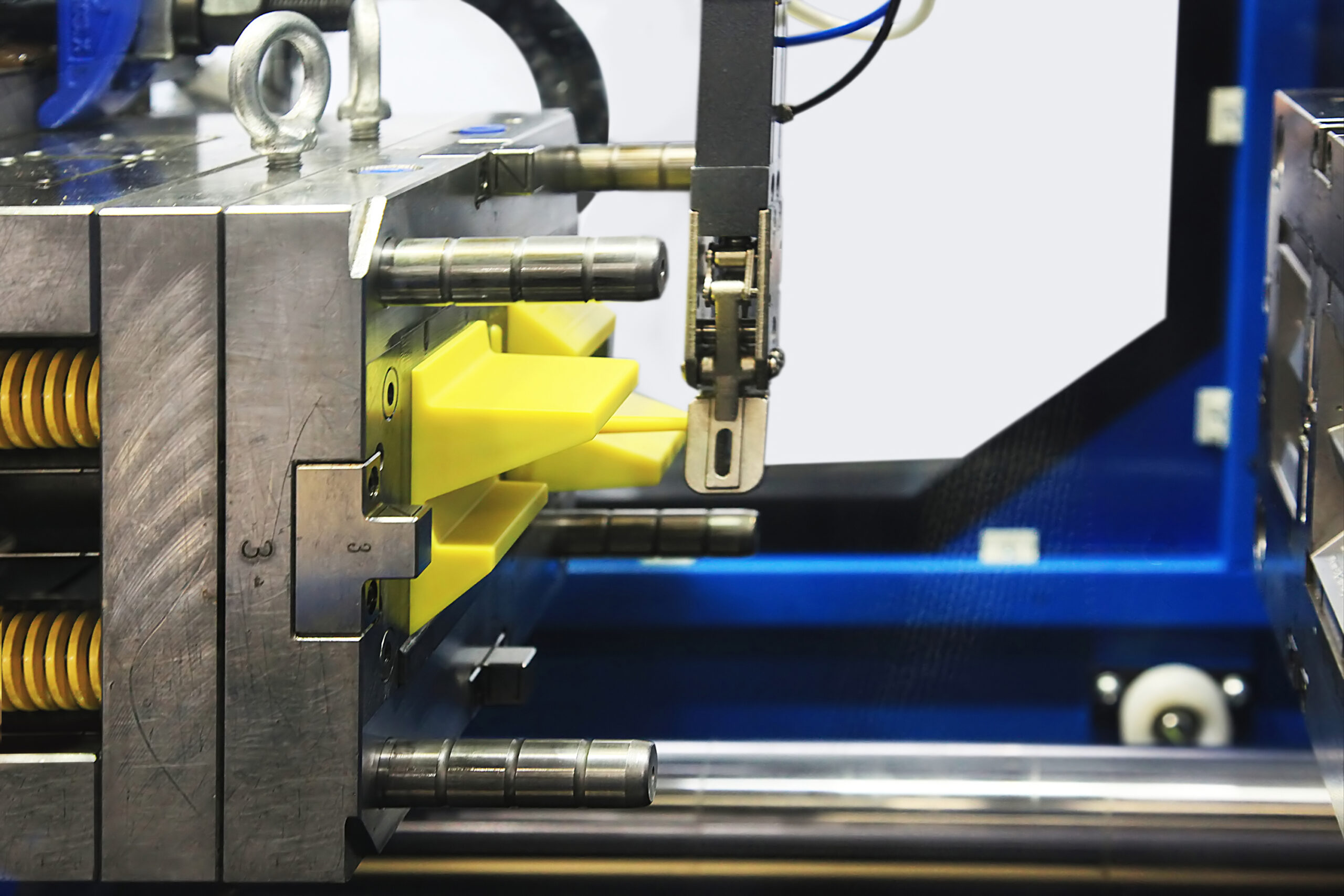

Dry ice blasting is a process for cleaning that utilizes dry ice pellets as the cleaning medium. These pellets are made of solid carbon dioxide (CO2) and are blasted onto surfaces at high speed using specialized equipment. When the dry ice pellets strike the surface, they undergo a rapid phase change from solid to gas, a process known as sublimation. This sudden change creates a micro-explosion that loosens contaminants from the surface without causing damage.

What sets dry ice blasting apart from other cleaning methods is its non-abrasive nature. Unlike sandblasting, which can erode surfaces, or chemical cleaning, which can leave harmful residues, dry ice blasting is gentle yet highly effective. The process leaves no secondary waste because the dry ice sublimates entirely, leaving only the dislodged contaminants to be cleaned up. This makes it an environmentally friendly option for fire damage restoration.

Benefits of Dry Ice Blasting for Fire Damage Restoration

Dry ice blasting offers several key benefits that make it an ideal choice for fire damage restoration:

Non-Abrasive Cleaning

One of the most significant advantages of dry ice blasting is its non-abrasive nature. This makes it safe for use on delicate surfaces, such as wood, brick, and electrical components. It effectively removes soot, char, and other residues without causing further damage to the underlying materials. This preservation of structural integrity is crucial in fire damage restoration, where the goal is to restore the property to its pre-loss condition.

Efficient Soot and Smoke Removal

Soot and smoke residues can be particularly challenging to remove, especially from porous surfaces. Dry ice blasting excels in this area by penetrating deep into crevices and pores, effectively lifting and removing stubborn residues. Additionally, the cold temperature of the dry ice pellets helps to neutralize odors, making it an excellent choice for eliminating the lingering smell of smoke.

Environmentally Friendly

Dry ice blasting represents an eco-conscious cleaning technique. Since the dry ice sublimates into CO2 gas, there is no secondary waste to dispose of, unlike sandblasting, which leaves behind abrasive material. Additionally, dry ice blasting does not involve the use of harmful chemicals, making it safer for both the environment and the restoration technicians.

Reduced Downtime

Time is of the essence in fire damage restoration, as prolonged exposure to soot and smoke can cause further deterioration of the property. Dry ice blasting is a faster cleaning process compared to traditional methods, allowing for quicker recovery and less downtime. This efficiency is particularly beneficial in commercial settings where business operations need to resume as soon as possible.

Applications of Dry Ice Blasting in Fire Damage Restoration

Dry ice blasting is versatile and can be applied to various aspects of fire damage restoration:

- Structural Cleaning: Dry ice blasting is effective in cleaning structural elements such as walls, ceilings, and floors. It removes soot, char, and other residues without damaging the building materials, preserving the integrity of the structure.

- Electrical Components: One of the unique advantages of dry ice blasting is its ability to clean electrical components safely. Since the process is non-conductive and leaves no moisture behind, it is ideal for cleaning soot-covered electrical panels, wiring, and equipment, ensuring they can be safely restored to working condition.

- HVAC Systems: Fire-damaged HVAC systems can circulate soot and odors throughout a building if not properly cleaned. Dry ice blasting effectively cleans the interior surfaces of ducts and other components, restoring air quality and system functionality.

Comparing Dry Ice Blasting to Traditional Cleaning Methods

When compared to traditional cleaning methods, dry ice blasting offers several distinct advantages:

- Effectiveness: Dry ice blasting is more effective at removing soot and smoke residues than methods like sandblasting or chemical cleaning. Its ability to reach deep into crevices and its non-abrasive nature make it superior for delicate surfaces.

- Cost-Effectiveness: While the initial cost of dry ice blasting equipment may be higher, the long-term savings are significant. The reduced labor time, lack of secondary waste, and elimination of chemical disposal costs make dry ice blasting a cost-effective choice for fire damage restoration.

- Safety: Dry ice blasting is safer for both the environment and the restoration crew. There is no need for harsh chemicals, and the process leaves no toxic residues. Additionally, since it does not generate abrasive dust, there is less risk of respiratory issues for workers.

Contact Our Team Today

Dry ice blasting has revolutionized the fire damage restoration industry by providing a faster, safer, and more effective cleaning solution. Its non-abrasive nature, efficiency in soot and smoke removal, environmental benefits, and reduced downtime make it the preferred choice for restoration professionals. Whether you are dealing with structural cleaning, electrical components, or HVAC systems, dry ice blasting offers a versatile and highly effective method for restoring fire-damaged properties.

If you are in need of professional dry ice blasting services for fire damage restoration, contact our team at Raw Restoration Blasting in Burlington, WI. We are dedicated to providing top-quality restoration services that help you recover from fire damage quickly and efficiently. Call us today at (262) 417-6836 to request a free estimate and learn more about how we can assist with your restoration needs.