In industrial settings, keeping machinery clean is essential to maintaining smooth operations. Press cleaning, in particular, is crucial for ensuring that printing presses, manufacturing machines, and other heavy-duty equipment function efficiently. However, cleaning these machines can be tricky because you need to avoid damaging sensitive components while still removing grime, ink, and other buildup. That’s where dry ice blasting comes in as an innovative solution. In this blog, we’ll dive into what dry ice blasting is, how it works, and why it’s one of the best options for press cleaning.

What Is Dry Ice Blasting?

So, what exactly is dry ice blasting? Imagine using tiny pieces of dry ice (which is basically frozen carbon dioxide) and shooting them at high speeds toward a dirty surface. As these dry ice pellets hit the surface, they break apart and evaporate, blasting away dirt, grime, and debris. What makes dry ice blasting special is that it doesn’t leave behind any residue because the dry ice evaporates, turning directly from a solid into a gas.

For press cleaning, this is particularly helpful because presses have a lot of parts that need to be cleaned without being damaged. Dry ice blasting doesn’t use any harsh chemicals or abrasive materials, so it cleans surfaces without scratching or wearing them down. Plus, because the dry ice disappears, there’s no need to worry about cleaning up after the cleaning process!

Benefits of Dry Ice Blasting for Press Cleaning

Now that we know what dry ice blasting is, let’s talk about why it’s such a great option for press cleaning. There are several key benefits that make this method stand out:

- Non-Abrasive Cleaning:

Unlike traditional cleaning methods that might involve scrubbing or using harsh chemicals, dry ice blasting is gentle on press components. This means there’s no risk of scratching or damaging sensitive parts, which is important for maintaining the integrity of the machinery. - Environmentally Friendly:

Since dry ice blasting doesn’t use any chemicals, it’s a much greener option compared to other cleaning methods. The only material involved is carbon dioxide, which is a naturally occurring gas. There’s no chemical runoff to worry about, and the process is completely safe for the environment. - Fast and Efficient:

Dry ice blasting is fast. The tiny pellets of dry ice can quickly clean large areas, which helps minimize downtime for your equipment. In industrial settings, every minute of downtime can be costly, so the speed of dry ice blasting is a huge plus.

Comparison With Other Cleaning Methods

When you think of cleaning methods for industrial equipment, you might picture chemical cleaning, pressure washing, or manual scrubbing. Let’s compare these options with dry ice blasting to see why it’s such a smart choice.

Chemical Cleaning

Chemical cleaners are effective, but they can be harsh and leave behind residues that may damage the press over time. They also require careful handling and disposal, adding complexity to the cleaning process. By contrast, dry ice blasting uses no chemicals and leaves no mess behind.

Pressure Washing

Pressure washing involves spraying water at high pressure to remove dirt. While this works well for some surfaces, it can be too harsh for delicate press components. Plus, it involves water, which can lead to rust or corrosion. Dry ice blasting, on the other hand, is completely dry, making it ideal for equipment that shouldn’t get wet.

Manual Scrubbing

Scrubbing by hand is labor-intensive and time-consuming. It’s also difficult to clean all the nooks and crannies of industrial presses this way. Dry ice blasting is faster, more thorough, and doesn’t require much manual effort.

In terms of safety, speed, and cost-effectiveness, dry ice blasting wins out over these traditional methods. It offers a safer alternative to chemical cleaners, works faster than manual scrubbing, and doesn’t carry the risks of water damage like pressure washing.

Applications in the Press Industry

Dry ice blasting isn’t just limited to one type of press or machinery. It can be used in various industries, making it a versatile solution. Here are a few examples of where dry ice blasting shines in the press industry:

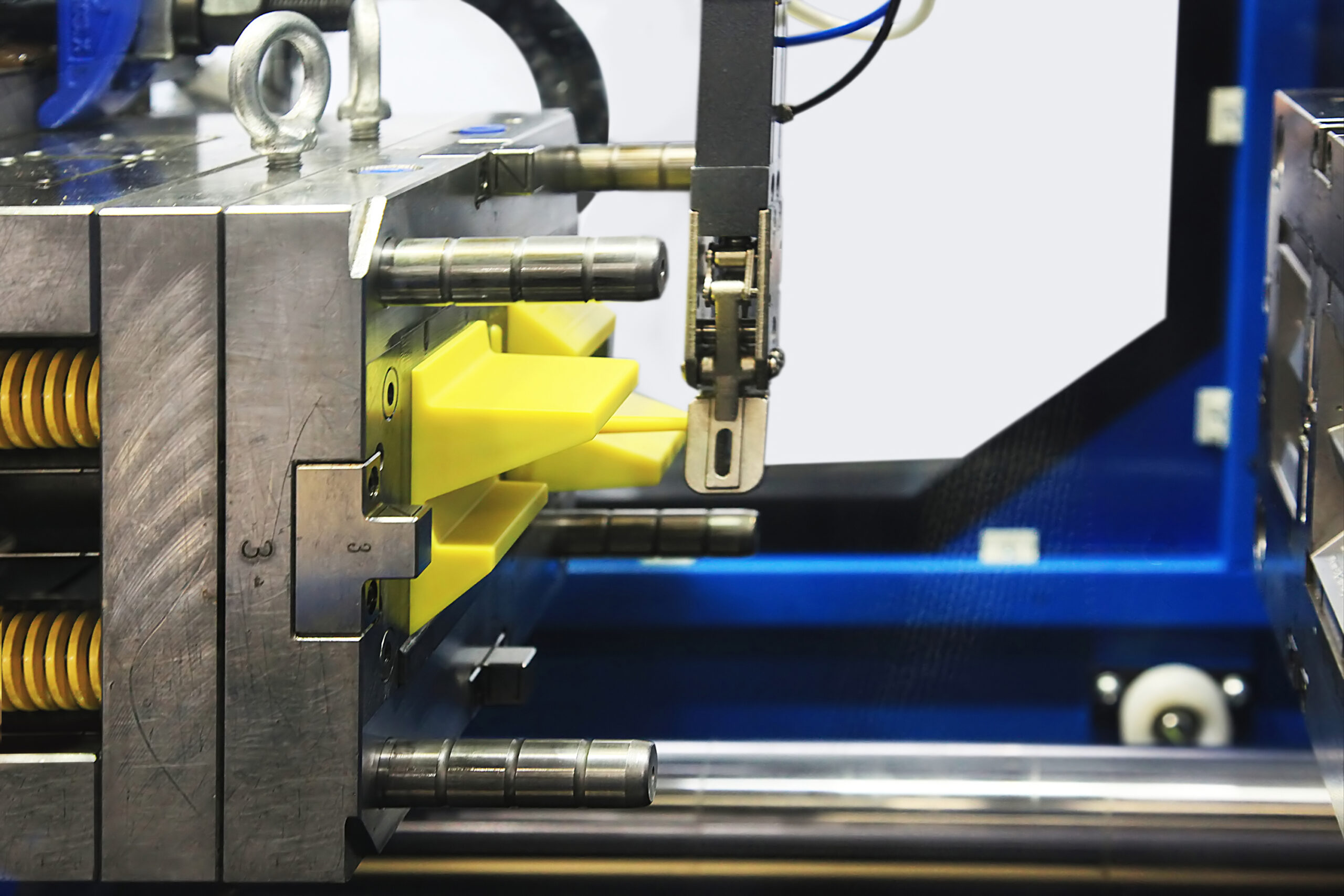

- Printing Presses: In printing, ink buildup can be a real issue. Dry ice blasting easily removes ink and debris without damaging the press rollers or other delicate parts.

- Manufacturing Equipment: In factories and plants, dry ice blasting can be used to clean production presses and machinery. This helps maintain production speed and keeps the equipment running smoothly.

- Food Processing Plants: Dry ice blasting is also used in industries like food processing, where hygiene is critical. It’s safe for cleaning machinery without contaminating the equipment with chemicals or water.

There are countless success stories from industries that have adopted dry ice blasting as their go-to method for press cleaning. Not only does it extend the lifespan of their equipment, but it also keeps operations running smoothly by reducing the need for lengthy clean-up processes.

Why Choose Dry Ice Blasting for Your Press?

So, why should you consider dry ice blasting for your press? There are long-term benefits that make this method worth the investment. First, because it’s non-abrasive, it helps your press last longer. By avoiding damage to sensitive parts, you can delay costly repairs or replacements.

Second, dry ice blasting is incredibly efficient. It reduces downtime, so your equipment can get back to work faster. Time saved on cleaning means more time for production and less time dealing with maintenance. Finally, it’s a safer and more environmentally friendly option, helping you comply with regulations without sacrificing cleanliness.

When choosing a service provider for dry ice blasting, look for a company with experience and the right equipment. Not all cleaning services offer dry ice blasting, so it’s important to find experts who understand how to safely and effectively clean your press.

Contact Our Team Today

Dry ice blasting is one of the best options for press cleaning. It offers a non-abrasive, eco-friendly, and highly efficient way to keep your equipment in top shape. Whether you’re dealing with stubborn ink buildup on a printing press or grime on manufacturing equipment, dry ice blasting gets the job done quickly without causing damage.

To learn more about our dry ice blasting services and how they can help you, contact our experts at Raw Restoration Blasting in Burlington, WI, by calling (262) 417-6836 to request a free quote.